Usage conditions:

Altitude not exceeding 1000M

Maximum ambient temperature+40 ℃

Minimum ambient temperature -45 ℃

Maximum monthly average temperature+30 ℃

Maximum annual average temperature+20 ℃

Installation location: It should be installed in a place without fire, explosion hazard, chemical corrosion, and severe vibration.

Product features:

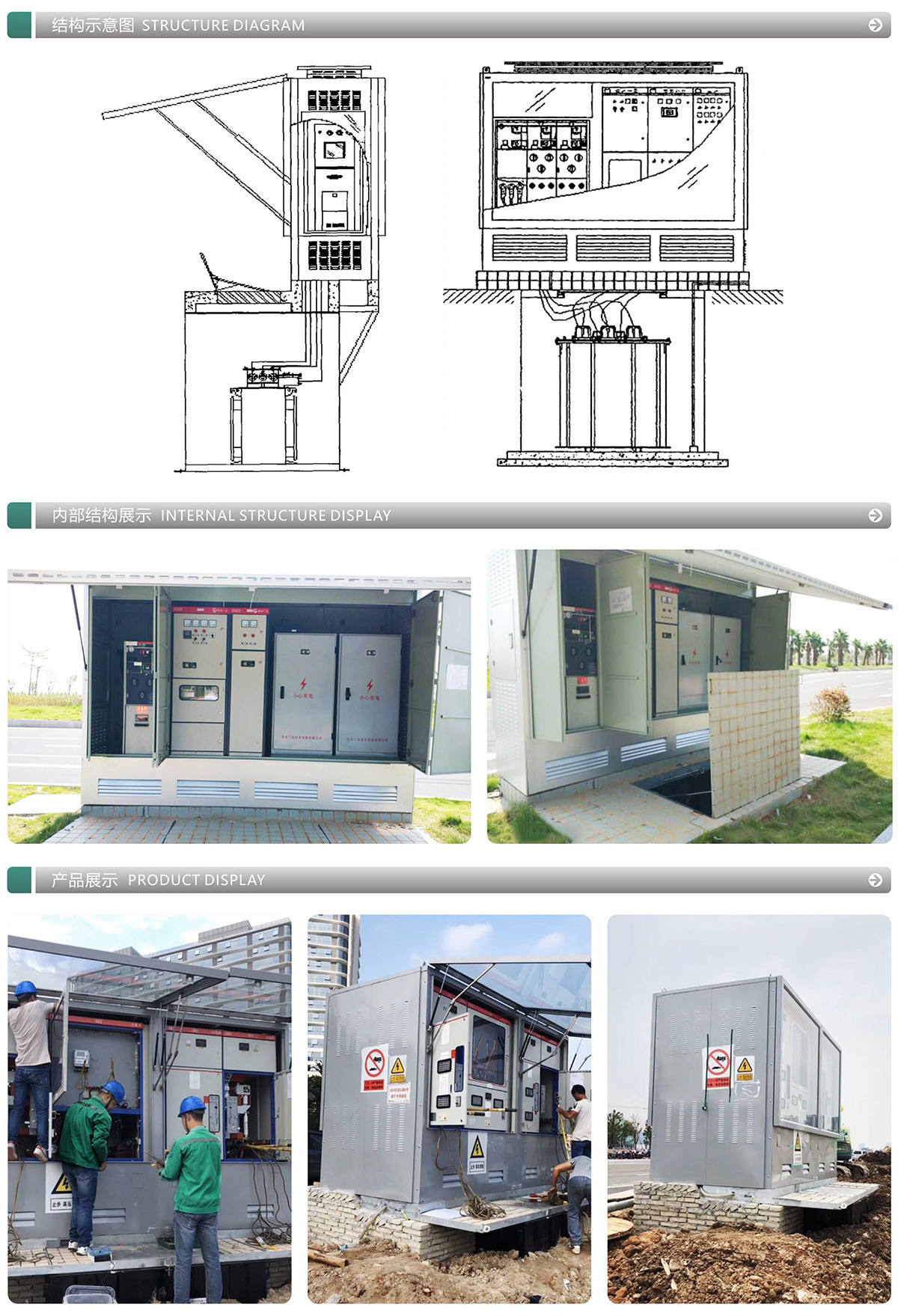

The underground box transformer has the characteristics of corrosion resistance, waterproofing, low temperature rise, low noise, easy installation, and maintenance free: it is a typical energy-saving product.

The fuel tank is made of low alloy structural steel, which has excellent comprehensive mechanical properties, welding performance, and low-temperature toughness. The box body adopts hot zinc spraying technology supplemented by plastic spraying treatment, which has strong corrosion resistance.

Adopting a fully sealed structure, the exposed parts of the high and low voltage terminals are isolated from the environment through imported sealed waterproof materials. When installing the local buried transformer, it is placed in the ground resistance. When the local pit is submerged or even submerged, it can still operate safely, resist floods, and effectively improve the reliability of the power supply system.

Adopting a unique heat sink structure, ensuring the heat dissipation and rust prevention capabilities of the heat sink.

The protective casing of the low-voltage cabinet adopts a patented outdoor lightbox type protective casing, and both sides of the lightbox type casing can be installed with all-weather advertising boards. It adopts small, green, and energy-saving LED luminous components.

The foundation of the underground transformer is a prefabricated structure, which can be flexibly prefabricated using different materials according to customer requirements.

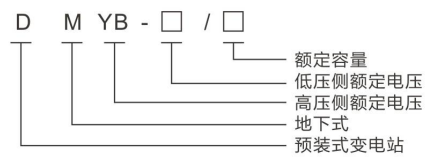

Box structure:

The underground part of the transformer room is welded with steel plates, which is a watertight structure that can effectively prevent groundwater from entering the room.

The bottom frame and support of the switch room on the ground are made of channel steel and angle steel, which have high mechanical strength. The switch room shell is made of materials such as aluminum alloy plate and stainless steel plate, and there are no traces of threaded connections or riveting on the exposed surface. The box is smooth and beautiful.

The box cover is lined with insulation material, which can effectively prevent the thermal radiation of the sun and reduce the occurrence of condensation.

Each room in the substation is separated into independent compartments by partitions. Layout of each compartment.

The outdoor doors of each switch in the substation are opened outward and sealed with rubber door seals to enhance their moisture-proof ability.

All Ferrous materials in the substation are subject to phosphating pretreatment, which can ensure that they will not rust for a long time.

Follow us

WeChat scan